|

| Carbon Fiber Aerogel Made from Raw Cotton |

|

Due to their low cost, rich source, nontoxicity to humans, etc., materials from nature are receiving increasing attention. Herein, we have produced lightweight, and porous aerogels which is composed of twisted carbon fibers (TCF) (Figure A) through a facile route by using cotton fibers as raw materials. The TCF aerogel is superhydrophobic indicated by the mirror-reflection in Figure B. The aerogel can not only adsorb the pollutants on the water (For example, heptane stained with Sudan red 5B in Figure C), but also adsorb the pollutants at the bottom of the water (For example, chloroform stained with Sudan red 5B in Figure D). The aerogel can adsorb a wide range of organic solvents and oils with a maximum sorption capacity up to 192 times the weight of the pristine TCF aerogel. In addition, the aerogels have a good recyclability.

|

Publications: H.C. Bi, Z.Y. Yin, X Cao, X Xie, C Tan, X Huang, B Chen, F Chen, Q Yang, X Bu, X Lu, L.T. Sun*, H. Zhang*, “Carbon Fiber Aerogel Made from Raw Cotton: A Novel, Efficient and Recyclable Sorbent for Oils and Organic Solvents”, Advanced Materials, DOI: 10.1002/adma.201302435(2013).

|

| Spongy graphene as a highly efficient and recyclable sorbent |

|

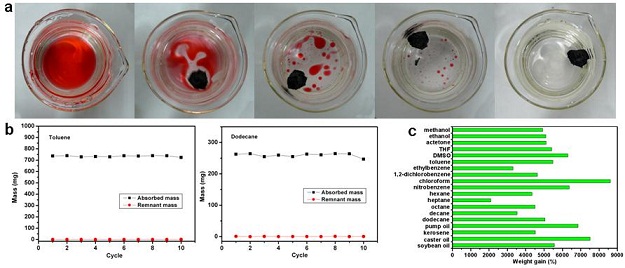

| (a~b) Low magnified and high magnified images of spongy graphene, respectively. (c~e) Wettability for water and dodecane, respectively. |

|

| (a) Dynamic absorption of spongy graphene towards dodecane (intervals: 20 seconds). (b) Recyclability of spongy graphene for Toluene and Dodecane. Spongy graphene could be regenerated (>10 times) by heat treatment yielding the full release of adsorbates (>99%). (c) Absorption efficiency of spongy graphene. Spongy graphene shows highly efficient absorption of not only petroleum products and fats, but also common toxic solvents. |

Publications: 1.Hengchang Bi, Xiao Xie, Kuibo Yin, Yilong Zhou, Shu Wan, Longbing He, Feng Xu, Florian Banhart, Litao Sun, and Rodney S. Ruoff “Spongy Graphene as a Highly Efficient and Recyclable Sorbent for Oils and Organic Solvents"Advanced Functional Materials 22, 4421-4425 (2012)  |

|

|

Carbon Nanotubes as High-Pressure Cylinders

|

|

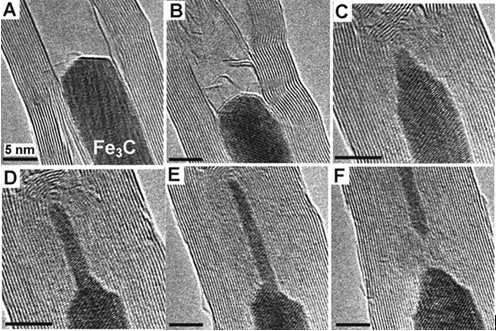

| We have discovered the Compression of a carbon nanotube filled with Carbon nanotubes can be used as pressure cells for the deformation of crystalline materials that are encapsulated inside the hollow cores of the tubes. Electron irradiation leads to a shrinkage of the tube and, thus, to deformation and extrusion of the crystalline core. The pressures inside collapsing nanotubes can reach values higher than 40 gigapascals. |

|

| Evolution of a MWNT partly filled with a Fe3C nanowire under electron irradiation with an electron beam during a total period of 50 min at a specimen temperature of 600°C (A) Tube before irradiation. (B to E) Irradiation leads to a collapse of the tube and deformation of the Fe3C crystal. (F) Tube collapse cuts off the thinned Fe3C crystal. Different sets of lattice planes are seen in (A), (B), and (C) to (F). Scale bars, 5 nm. |

| Publications: L. Sun, F. Banhart, A. Krasheninnikov, J.A. Rodriguez-Manzo, M. Terrones, P.M. Ajayan“Carbon nanotubes as high-pressure cylinders and nano-extruders" Science 312, 1199 (2006) |

Carbon Nanotubes as nanoresonators

|

|

|